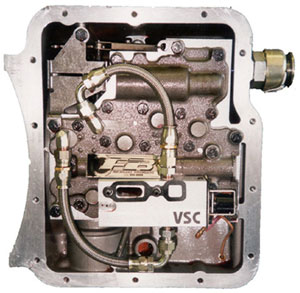

Description: The VSC (Variable Stall Control) option is built into the "full manual" valvebody of your transmission. It is intended to provide you with means to increase the stall of a torque converter during the initial launch of the car. This option operates by activating and deactivating its own (self-grounded) electrical (12V)  solenoid. Since the VSC is built into the transmission's hydraulic system it will provide a higher stall rpm for any torque converter with which it is used. However, it is specifically designed to for use with a torque converter that has a lower stall rpm, than a converter that would normally be used with your application. (A "tighter" or lowered stall converter will provide a much greater coupling rate and efficiency.) Each of the VSC equipped valve-bodies are dyno-tested and checked to insure that they engage properly and provide a benchmark stall variation with the same "test" torque converter. However, the amount of actual stall variation is dependent upon two (2) important factors regarding the torque converter to be used in your car: The amount of torque your engine produces at the preset rpm stall speed and the converter's size and configuration.

solenoid. Since the VSC is built into the transmission's hydraulic system it will provide a higher stall rpm for any torque converter with which it is used. However, it is specifically designed to for use with a torque converter that has a lower stall rpm, than a converter that would normally be used with your application. (A "tighter" or lowered stall converter will provide a much greater coupling rate and efficiency.) Each of the VSC equipped valve-bodies are dyno-tested and checked to insure that they engage properly and provide a benchmark stall variation with the same "test" torque converter. However, the amount of actual stall variation is dependent upon two (2) important factors regarding the torque converter to be used in your car: The amount of torque your engine produces at the preset rpm stall speed and the converter's size and configuration.

Stall Test: The valvebody is also equipped with an FB trans-brake. To determine the amount of rpm stall variation the VSC will give your converter, a simple stall test is required. Using the trans-brake, a stall test should be done with the VSC deactivated to first determine the actual preset stall rpm of the converter. A second stall test is then performed with the VSC activated to observe the amount of stall increase. (Use toggle switch for on/off 12V to VSC). When the VSC is activated the same amount of engine torque at the preset stall speed will produce a higher stall rpm. As higher engine rpm is achieved, higher torque may also be produced and continue to increase the stall speed. It is not uncommon to see a stall increase of 800 to 1000 rpm. It is very important to correctly choose the right torque converter stall initially. The results from each of these stall tests should be noted and forwarded to FB for evaluation.

Launch Operation: There are a number of methods for operating the VSC system with your transmission and torque converter during the launch phase of the car. Each of these methods involves both the electrical "activation" and "deactivation" of the VSC. Since the VSC is used primarily during the launch, the activation of the trans-brake and the VSC can happen simultaneously and should be wired accordingly. (See schematics). The deactivation of the VSC can be done by any one of four (4) ways:

a) Release of the trans-brake switch at the desired launch rpm

b) When the engine rpm of a preselected rpm chip is reached.

c) When the preselected pressure of an adjustable (0 - 30 psi) absolute pressure switch is reached.

(This type of switch is normally installed in the manifold of turbo-charged motors).

d) When the time of a preselected timing relay is reached.

These are a few of the suggested methods for operating the VSC system during the launch of the car. Keep in mind that the VSC like the trans-brake is a momentary type device and is not intended to be activated for any length of time. Misuse of this option can have detrimental effects to both the transmission and torque converter.

High Gear Operation: The VSC option can also be used to "soften" the high gear shift. Since the torque converter that is used with the VSC has greater coupling efficiency, it will tend to pull the rpm speed of the engine down at the high gear shift. Especially with an engine whose torque curve changes dramatically at the shift rpm point. The VSC unit can be activated just prior to the shift point and deactivated after the shift is made. There are many methods to achieve this function. We would recommend a smart type relay, that can be activated by an rpm switch and deactivated by a time function. How ever, whichever approach is used, keep in mind that it must occur only once and reset after the run is complete.

IMPORTANT: Converter Pressure must be monitored when using the VSC option. Use an in-line sending unit to an oil pressure gauge ( 0-100 psi) in the cockpit . The bottom oil fitting on the transmission is "fluid out" to cooler. (50 to 80) psi is normal with VSC off and (0 to 15) psi with VSC on.

NOTE: When the trans-brake is initially activated (with the VSC off) the cooling line pressure will normally drop. This pressure drop will also occur at low engine rpm. However, in the event a reading below 20 psi occurs with the VSC off, the transmission in gear, and the engine at high rpm: Shut off engine immediately. This low pressure can cause damage.